11/27/2012: Rather than create separate blog entries for each visit to this location, I simply insert a new "Trip Notes" section below to describe the visit and display some of the day's pics. Any additional pictures taken are then added to the slideshow (when applicable) at the bottom of the post. Scroll down to the 11/27/2012 Trip Notes section to read the latest update.

{Click on an image to enlarge, then use the back button to return to this page}

|

| (Fig. 01) |

|

|

| (Fig. 02) Click picture to enlarge |

|

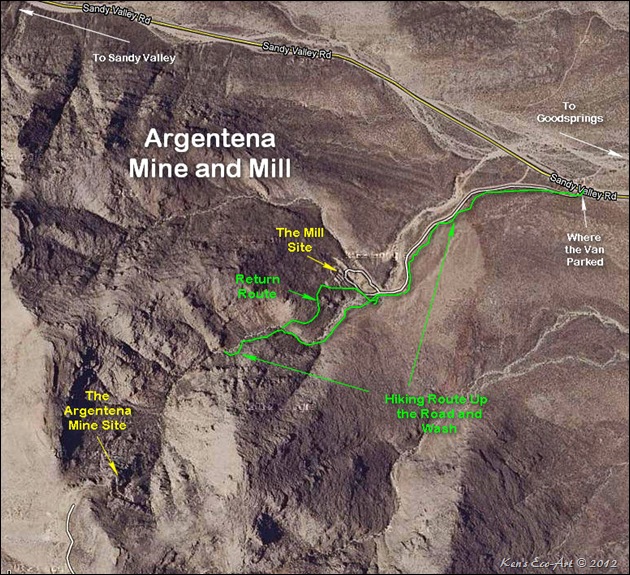

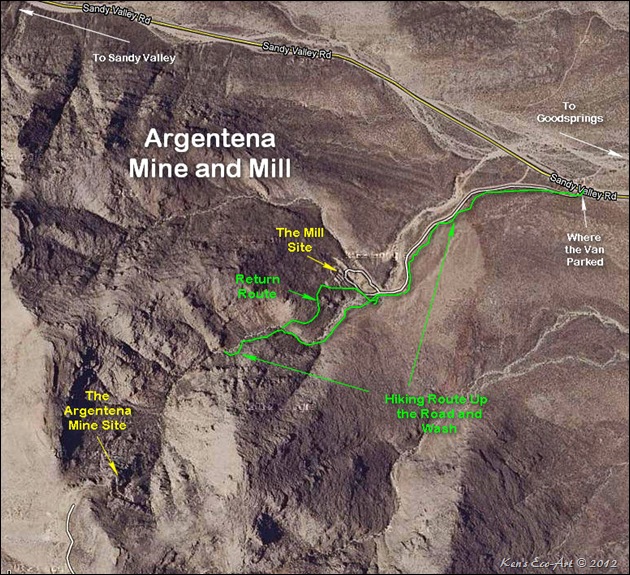

Mine & Mill Description: The Argentena Mine and mill (Fig. 02) is located in the Goodsprings Mining District, SW of Goodsprings, in Clark County, just a few miles in on the south side of Sandy Valley road. The property was first owned by the Argentena Consolidated Mining Company. The present company was formed in 1927 and initiated an aggressive development programs as well as construction of the 60-ton flotation-gravity mill. An intermittent producer of lead-zinc-silver ore since 1926, the mine itself is high on a ridge along the eastern flank of Table Mountain at an altitude of 4,650 to 4,900 feet. The ore was lowered to the mill site (Fig. 01) on a 2,800 foot long aerial tramway approximately 1,000 below the mine itself. With nineteen ore buckets, it had a total capacity of 25-tons per hour. All ore produced came from four levels of stopes, with drifts extending for 1,200 feet along the strike.This structure is all that remains of flotation-gravity mill that included a pipeline and power line that ran from the town of Goodsprings. It was comprised of no less than eight levels (Figs. 14, 15, 17) that had been connected by a series of wooden water troughs used for separating the ore that arrived from the mine via the tramway. The small adit on the side of the hill next to the mill (Fig. 16) is reported to have been a storage area for explosives. Unfortunately, the mill proved to be a failure and, because of lack of market for a direct shipping ore, the mine was closed. It then operated sporadically from 1931 to 1942. In 1943 the mine was reopened, and ore was shipped to the Metals Reserve Company stock pile at Jean, NV. The mine was finally closed for good in July 1946 because of the removal of premium payments for lead and zinc.

After mining, large pieces of the ore feed are usually broken through some type of crushing and/or grinding process in order to obtain particles small enough where each particle is either mostly valuable or mostly waste. Concentrating the particles of value in a form supporting separation enables the desired metal to be removed from waste products. Because ore bodies often contain more than one valuable metal, the tailings of a previous process may be used as a feed in another process to extract a secondary product from the original ore. Additionally, a concentrate may contain more than one valuable metal. That concentrate would then be processed to separate the valuable metals into individual constituents. It has been suggested that the large carved out "room" shown in photo 13 may have been used as a storage area for explosives. |

|

|

| (Fig. 03) |

|

|

| (Fig. 04) |

11/27/2012 Trip Notes: Harvey Smith and I took a trip to the Sandy Valley area to do a little four-wheeling in search of the Argentina Mine. Though we have visited the mine’s mill site (Fig. 01) with the rock-hounds from the Henderson Senior Facility on a couple of occasions, no one in our group has ever been to the actual mine site. Visible from the top of the ridge behind the mill, the actual mine is at the top of a mountain more than a half mile away. Traveling about a mile and a half past the turnoff for the road to the processing site , refer to (Fig. 03), we turned onto Table Mountain Road. About a quarter mile in we used the “Ranger” (Fig. 04) to transverse the rest of this rough and rocky road. About two miles in we head east up a road to the ridge where we think the mine should be. Along the way we stopped and explored more than a half dozen other mines (Figs. 05 thru 08). Near the top of this road we got out and hiked up over the ridge and down to the Argentina Mine site. |

| |

|

| (Fig. 05) |

|

|

| (Fig. 06) |

|

|

| (Fig. 07) |

|

|

| (Fig. 08) |

|

| After hiking around the ridge, a trail led down to the mine sites. We were surprised to learn that there was no real ‘large’ mine, but rather five smaller mines, some reportedly more than 1,200 feet in length. If you look carefully at (Fig. 09) you can see a string of four of these mines coming down the hill. Directly below these adits, directly below where Harvey is standing in (Fig. 09) was a very large ‘carved’ out area, (Fig. 10), that was the base of the very large tramway that carried 19 ore buckets back and forth to the processing facility more than 2,800 feet below. Because the various mine openings are so small, it is this area, filled with tons of cable, pulleys and steel ruminants from the cableway platform (Figs. 11-13), that is mistaken for the mine shaft when viewed from below. After visiting the Argentina Mine site we drove around for a while and eventually to the top of Table Mountain. Click the following link for pictures and more info … . |

|

| (Fig. 09) |

|

|

| (Fig. 10) |

|

|

| (Fig. 11) |

|

|

| (Fig. 12) |

|

|

| (Fig. 13) |

|

|

11/08/2012 Trip Notes: On this most recent stop here with the rock-hounds from Henderson's Heritage Park Senior Facility, I decided to hike up the steep wash (Fig.18) that runs behind the mill to see what it revealed. Unfortunately, this led to very few pictures; the only findings were sightings of remnants of the platforms (Fig. 19) and support structures for the 2,800 foot-long cable-way that once ran from the mine to the mill. The final picture in (Fig. 20), taken on a previous visit, is a view of a snow capped Shenandoah Peak looking northwest as we walked down the road that paralleled the wash that leads to the site from Sandy Valley road.

|

|

| (Fig. 14) |

|

|

| (Fig. 15) |

|

|

| (Fig. 16) |

|

|

| (Fig. 17) |

|

|

| (Fig. 18) |

|

|

| (Fig. 19) |

|

|

| (Fig. 20) |

|

|

|